Design Engineer Role

In Semiconductor Wafer

Bonder Systems

STRICTLY NO AGENCIES!

About the Role

We are seeking a Design Engineer to strengthen our mechanical design capability and support both new product development and continuous improvement of existing platforms.

You will be working closely with the Design, Production and testing teams and be responsible for mechanical & electro-mechanical designs while contributing to continuous improvement of existing platforms and components. This role is hands-on and practical, involving precision mechanical design, vacuum-compatible systems, motion and drive mechanisms. After familiarisation and training you will be given responsibility for subsystems and complete design packages. You would be working in our office based at Library Avenue, on Harwell Campus but may occasionally be required to travel in the UK or abroad to support customers. The hours of work are 8.30am to 5pm with 45 minutes for lunch.

About AML

Applied Microengineering Ltd. (AML) is a well-established manufacturing company supplying specialist equipment to the semiconductor industry. Established in 1992, we have been designing and building integrated wafer-aligning and bonding systems for more than 30 years and have a team of highly skilled engineers developing our machines. We supply systems to Universities, Research Institutes and commercial companies, for use in R&D and production environments and are proud to be able to supply to a worldwide market.

Detailed Role requirements

Click on each section to expand it for more information:

• Produce high-quality SolidWorks models, assemblies, and fully toleranced manufacturing drawings in accordance with AML and international standards

• Support prototype build, system assembly, testing, and commissioning, resolving design issues as they arise

• Provide technical support to production, including:

• Troubleshooting mechanical and electromechanical issues

• Improving part designs for reliability, manufacturability, and assembly

• Implementing design changes based on production / customer feedback

• Participate in design reviews, technical discussions, and risk assessments

• Work closely with suppliers to define manufacturing processes, tolerances, materials, and finishes

• Contribute to continuous improvement of the existing machine design

• Perform engineering calculations including stress, material selection, thermal considerations, tolerances, and structural integrity.

• Complex assemblies with moving parts

• Standardized engineering drawings

• Advanced GD&T, tolerance stack-ups, and fits

• Design intent suitable for precision manufacturing

• Experience designing components for tight tolerances, repeatability, and alignment-critical systems

• Ability to perform:

• Stress and deflection calculations

• Thermo-Fluid calculations

• Material selection trade-offs

• Use of analytical thinking to validate designs before manufacture

• Machining

• Sheet metal

• Surface treatments and coatings

• Understanding of:

• Lifecycle Analysis (LCA)

• Design for manufacture and assembly (DFMA)

• Rapid prototyping and iterative development

• Experience supporting products through multiple design revisions and production cycles

• A minimum of five years of industrial design experience, ideally in:

• Semiconductor equipment

• Vacuum systems

• Precision machinery

• Scientific or research instrumentation

• Proficiency in Microsoft Office 365 applications

• Comfortable taking ownership of subsystems and seeing designs through to completion

• Strong communicator, able to work effectively with design, production, and management

• Willing to get involved at the machine level when required

• Organised, methodical, and able to manage multiple tasks in a project-driven environment

• Ability to work independently and within a team environment

• Full Driving Licence advantageous

• Working knowledge of electrical engineering, including:

• Reading and understanding electrical schematics

• Familiarity with electronic components and control systems

• Experience with Electrical schematic software such as Zuken E3

• Ability to create renderings, animations, or visuals using:

• SolidWorks Visualize

• Adobe Illustrator / Photoshop

• After Effects or Premiere

• Familiarity with Blender for 3D modelling or animation

• Hands-on experience with rapid prototyping, including 3D printing

• Structural components and enclosures suitable for high and ultra-high vacuum

• Selection of vacuum-compatible materials, seals, fasteners, and surface finishes

• Integration of:

• Vacuum chambers

• Pumping systems (e.g. roughing, turbo, cryo – depending on application)

• Feedthroughs, valves, and viewports

• Understanding of:

• Outgassing considerations

• Thermal expansion in vacuum

• Cleanliness and contamination control

• Designing assemblies that allow easy maintenance and access while maintaining vacuum integrity

• Selection and integration of:

• Servo motors, stepper motors, and DC motors

• Linear stages, rotary stages, lead screws, ball screws, and belt drives

• Gearboxes, couplings, and bearings

• Mechanical design for:

• Precision alignment and repeatable positioning

• Load handling, stiffness, and vibration control

• Thermal effects on accuracy

• Experience integrating sensors and feedback devices, such as:

• Encoders

• Limit switches

• Proximity sensors

• Load or force sensors

• Ability to work alongside electrical engineers or technicians, understanding motor control requirements and installation constraints

• Profit related Christmas bonus

• 25 days annual leave plus 8 bank holidays

• BUPA Health Insurance

• Annual private health assessment

• Non-contributory Death in service policy - 4 x annual salary

• Free on-site parking

• External training programme

• Company pension

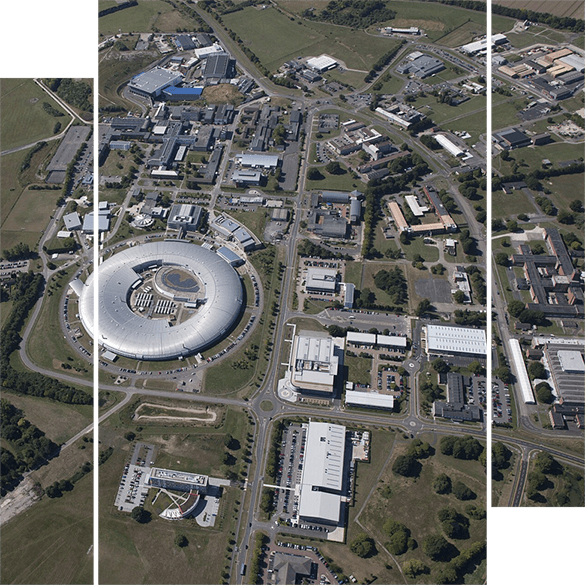

• Full use of Harwell Campus facilities: https://www.harwellcampus.com/life/

Life in Harwell Campus

Harwell is a research and innovation supercampus, home to a unique array of cutting-edge scientific facilities, institutes, businesses, and expert teams working to advance knowledge and find solutions.

Founded in 1946 as a hub for pioneering technology, our Oxfordshire campus is a unique collaboration between government, academia and industry, and now hosts over 7,000 scientists, engineers, entrepreneurs, and technicians – all focused on solving complex problems.