Why Rock?

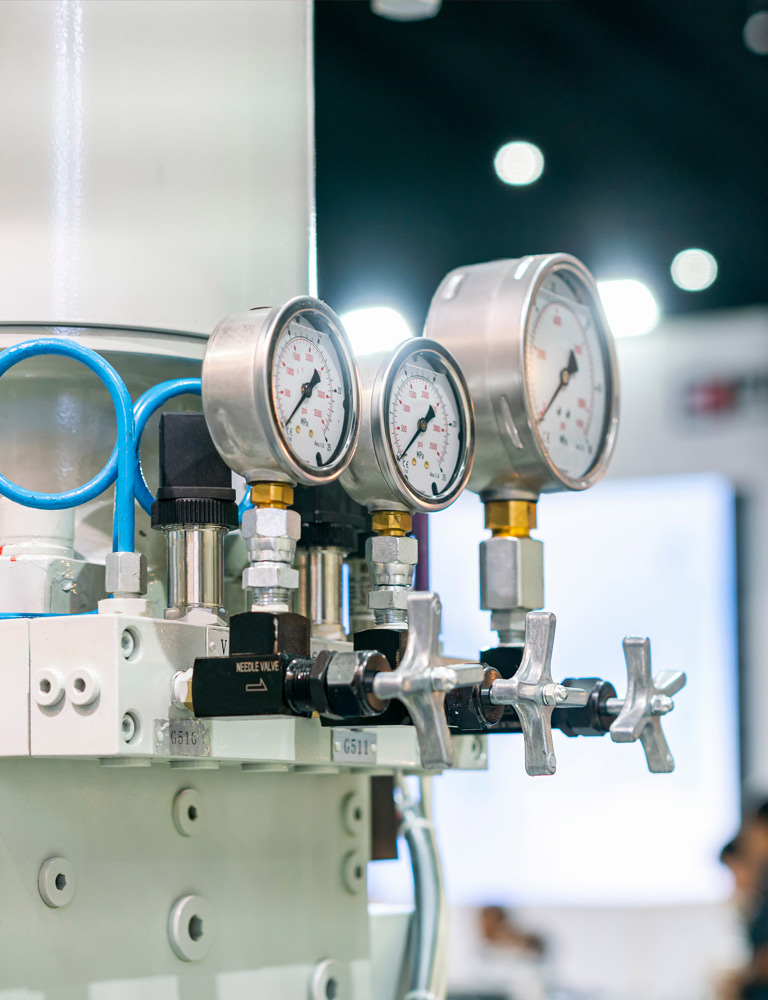

The Rock Aligner Bonders are designed for bonding under Ultra High Vacuum conditions, in the 10-8 mbar range.

The Rock systems offer the same aligning and bonding capabilities as the AWB systems, and the UHV vacuum levels are achieved through the use of fully-integrated Cryopump.

Configurations.

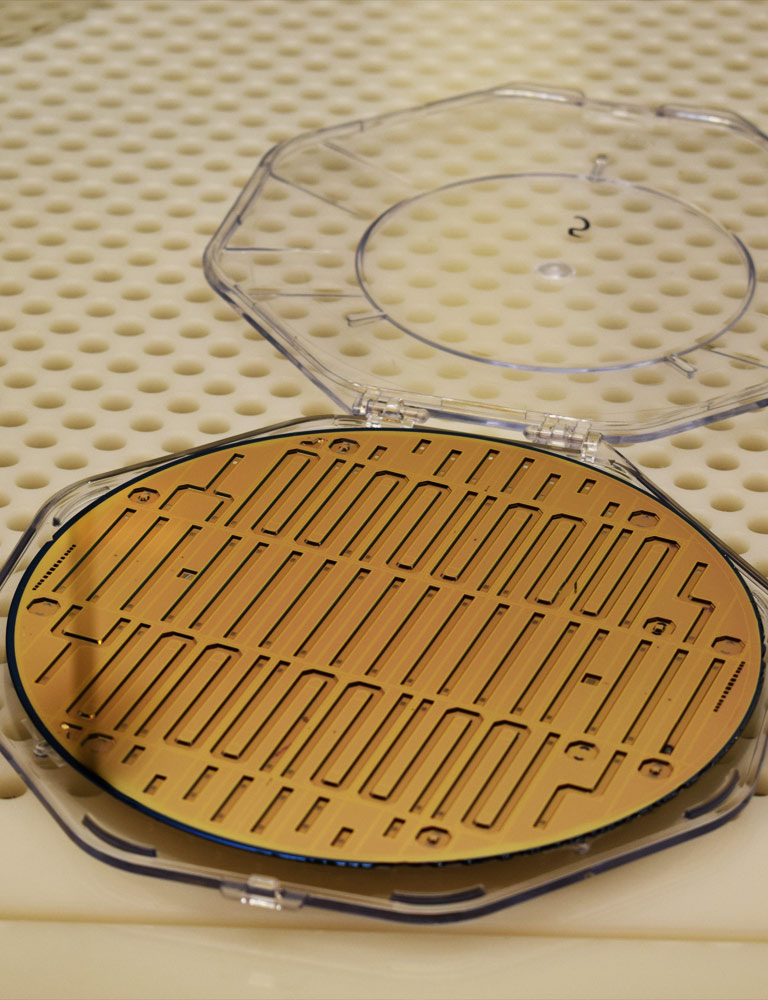

FOR 3", 4" & 6" WAFERS + CUSTOM CHIPS

ROCK 04

FOR 6" & 8" WAFERS

ROCK 08

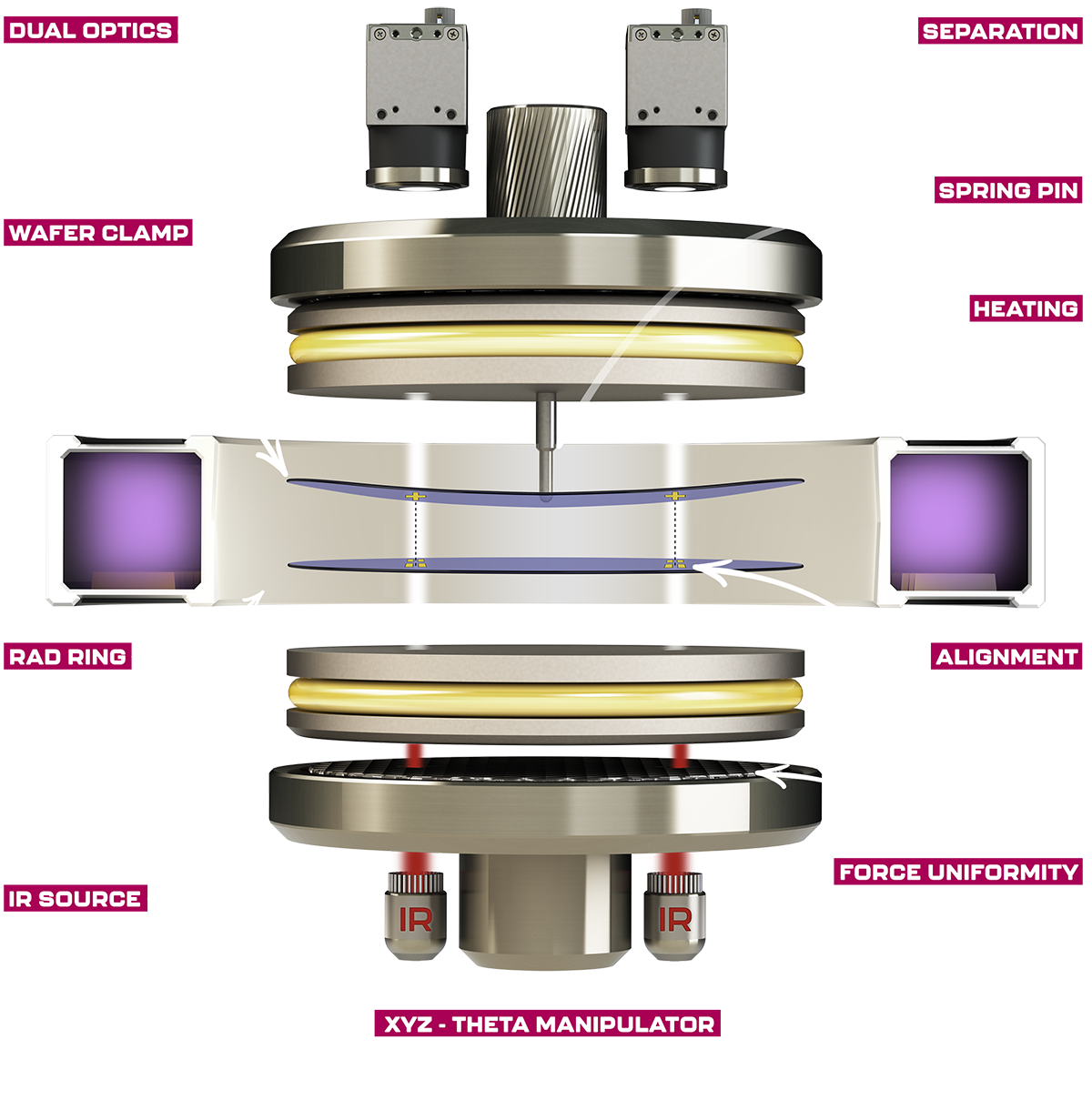

System schematic.

The diagram below is a representation of the components within the ROCK chamber.

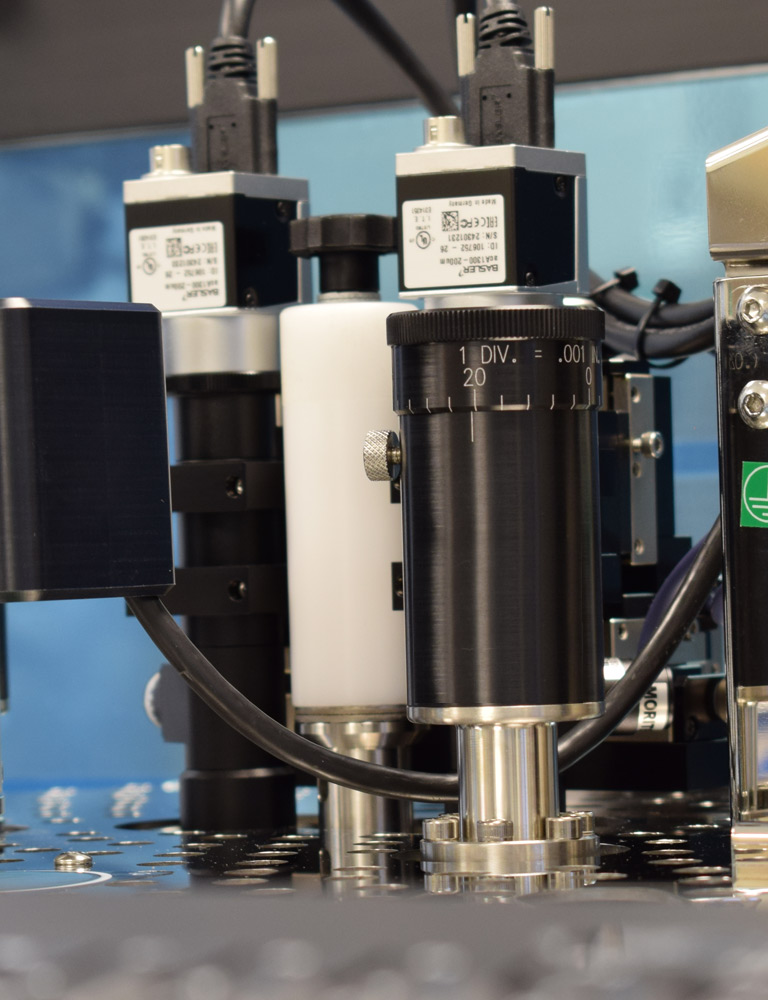

Key features of the ROCK.

In-situ alignment, independent wafer heating and radical activation are amongst many valuable features offered by the system, together with enhanced vacuum levels.

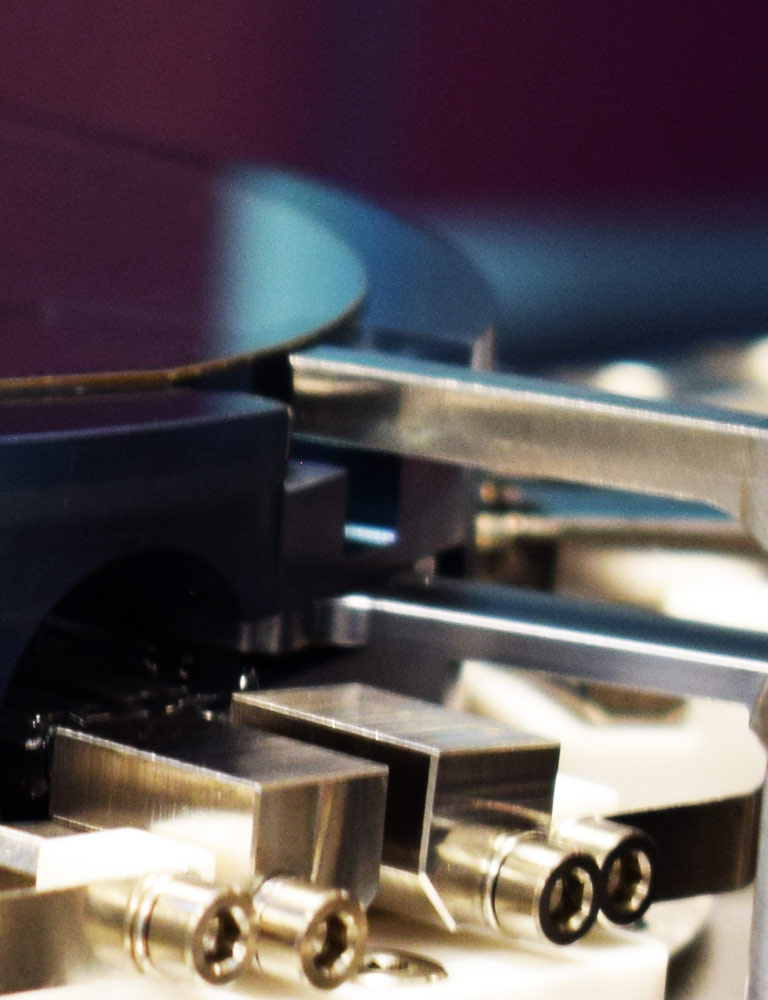

Edge Clamping ensures no contact with bonding surfaces and eliminates the risk of contamination or damage.

Bonding under vacuum or controlled pressure in the range 2.5 x 10-3 mbar and 2 bar absolute. Up to three process gas lines are available.

Motorised Z control to apply contact forces of up to 40kN.

Triple-stack anodic bonding of both combinations: silicon-glass-silicon and glass-silicon-glass is possible.

Optional components for UV cure adhesive bonding are available.

Optional NIR cameras sensitive beyond 1.1μm wavelength can replace the standard cameras if required.

A special upper platen for mounting of a chip can be offered. Custom size chips can be accommodated.

Did you know?

All AML systems are very flexible and switching between wafer sizes is a straightforward operation, with replacement of the platens taking less than an hour.