Wafer Separation.

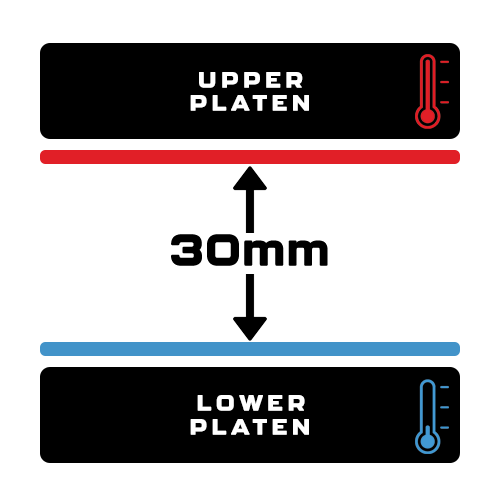

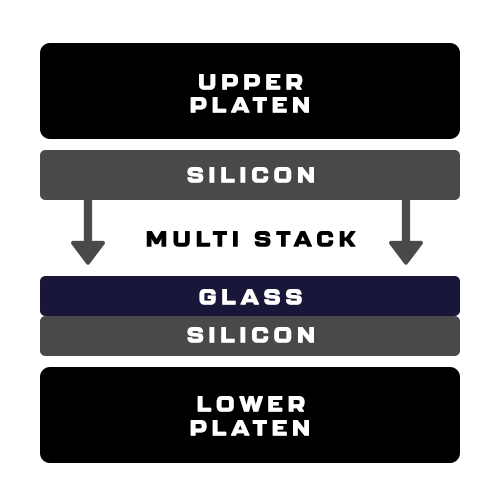

Wafers can be held apart, separated by up to 30mm, opening up process possibilities and providing a number of advantages.

Rapid and effective outgassing of the wafers and any cavities - particularly important where vacuum-encapsulation or gas-encapsulation is required.

The wafer separation is achieved by employing a fully automatic 4-axis manipulator where the Z drive provides up to a 30mm gap and applies up to 40kN contact forces.

The large separation allows independent heating of the upper and lower wafers allowing, for instance, getter activation at a higher temperature while keeping the other wafer cool.

Other benefits.

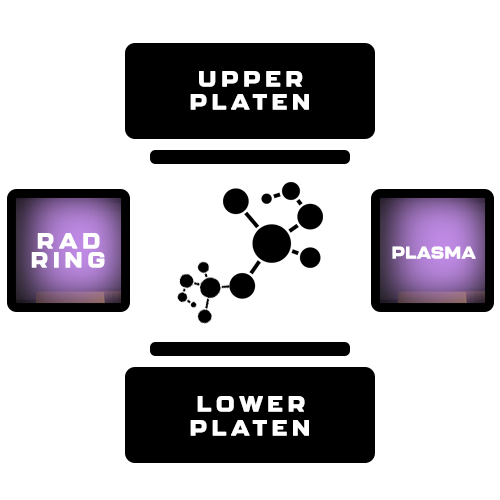

In-situ chemistry is also available with surface activation, reliable pressure control and vapour injection for oxide removal.

Bonding of thick wafers or a stack of wafers up to 30mm is possible.

Did you know?