The live view provides visual confirmation and allows last-minute corrections, ensuring post-bond accuracy. Alignment can be carried out at any desired temperature, eliminating inaccuracies due to thermal expansion and mismatch between wafers. The central pin is used to prevent contact shift.

Benefits

of In-situ

Alignment

All in One

Entire bonding process is done in one chamber without physically moving the wafers from aligner to the bonder

Adjust last minute

Possibility of making fine alignment adjustments just before contacting the wafers for bonding

Higher Throughput

Shorter cycle times – can align while system is being pumped down and wafers heated

Ability to re-align

Corrections possible – in some processes, if alignment at contact is not satisfactory, it’s possible to separate the wafers and start again

Align hot or cold

Can be carried out at any desired temperature, eliminating inaccuracies due to thermal expansion mismatch

No Contact Shift

Good “contact shift” control – alignment observed live while force is being applied to the wafers; also helped by using the central pin

Reliable Performance

Very useful for adhesive or glass frit bonding where low viscosity materials can be problematic while contacting the wafers

Did you know?

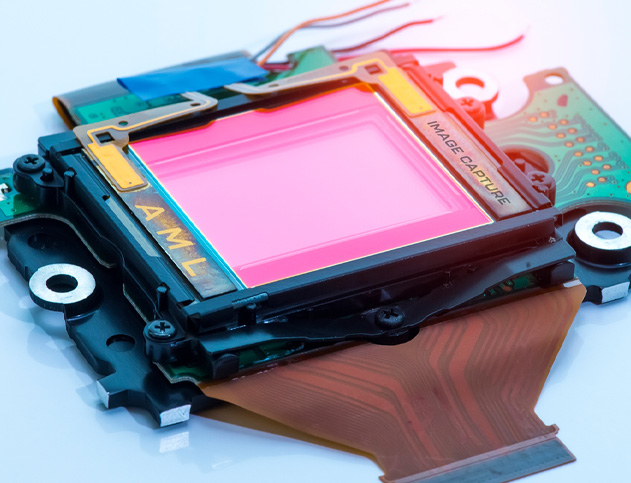

For backside alignment, an image capture option is available. Alignment can be performed manually or automatically.